Finally, the last day of our week-long harvest had arrived. All the activities we had left to complete were the final lot of oasting and packaging two rows of the Cascades. Before getting to work on that, I took a walk over to the hop yard for a look at it now that all the hops had been taken down.

Finally, the last day of our week-long harvest had arrived. All the activities we had left to complete were the final lot of oasting and packaging two rows of the Cascades. Before getting to work on that, I took a walk over to the hop yard for a look at it now that all the hops had been taken down.

We decided to leave the Fuggles and Goldings rows up for the rest of the growing season. We know there is demand for these varieties, but the plants definitely need another year to strengthen and adapt to our region. Hopefully they'll benefit from additional sun and time so that we'll see enough cones on them next year to have a first harvest.

|

| Here's a photo of the hops we harvest and packaged - totaling around 50 pounds - now they're off to brewers! |

From the Chinook, CTZ/Columbus, and the first two lots of Cascade hops, I pulled an eight ounce sample for testing at the Virginia Tech lab. We were pleased with the results - they were in line with expectations and the commercial ranges - and since the lab included a moisture assessment, we have the info we need to refine our oasting process for next year. It's great to have this asset in the community!

Incidentally, here are our alpha/beta results for the three varieties we harvested this year:

- Cascade (average of two lots): alpha 6.65%, beta 3.74%

- Chinook: alpha 8.84%, beta 2.39%

- CTZ/Columbus: alpha 13.23%, beta 3.52%

Our final yield of hops across these three varieties was about 50 pounds. We packed them as one-pounders for the craft brewers we are marketing, and 4-oz packs for home brewers. More on the marketing in a moment, because I want to mention a funny story that happened during the packaging.

We'd been working in David and Heather's garage on this process for the duration of the week. On Tuesday afternoon, Heather had put some spare concert tickets up for sale on Craigslist, and the eventual buyer came around to pick them up while David and I were in the middle of packaging the hops.

As you can see in the photo of our final product, this activity appears suspicious, since we're handling green plant material and packaging it in bulk - not to mention there is a lot of it.

So the buyer comes into the garage and asks for Heather. After a moment, he notices the bags of green product all around us - his eyes grew big as saucers before he turned to knock on the door and ask for her!

Over the course of the growing season we'd had some visits from brewers, and I had done a few other outreach activities to let everyone know about our first harvest. Once I had the lab results and quantities, I did some follow-up activities.

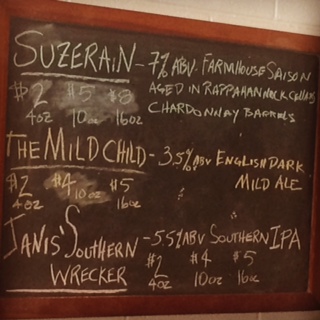

Soon we had orders from five craft breweries in Virginia, and we've also sold to home brewers in Florida, California, Pennsylvania, and Virginia! Needless to say, our success at selling the hops far exceed anything I expected. I can't wait to hear that they've got their beers ready and on tap - I hope to be able to make a visit to each one to celebrate!

So this post concludes the series on our first harvest at Hawksbill Hop Yards. What a great and unique insight being a hops farmer gives to the craft brewing industry! We have some expansion and improvement plans for the hop yard this fall and next spring, and then we'll get started again on the whole thing.

It's been a lot of fun, even though it was hard work the whole way. But to be honest, I can't wait until next year!